At 10:58 am, October 18th,2021, a DLT Industrial 4.0 Energy Efficiency BenchmarkDigitized&Intelligent Carboneutral Series doubledeck kiln for sinteredslabs was started up successfully in NewPearl Group’s 5G Green&SmartPlant in their Industrial Park.

The start-up ceremony received muchattention from the management of NewPearl Group. Mr. Ye Delin, Chairman of theBoard of Directors, Mr. Jian Runtong, Vice CEO, in company with managing teamand workers hosted the ceremony. As specially invited guests to jointly witnessthe grand and memorable event, Mr. Bian Cheng, Chairman and Mr. Yang Xuexian,Managing Director of Keda Industrial Group, accompanied by Mr. David Wu, SalesDirector of LT Brand, Mr. Jing Haishan, DLT Deputy Managing Director, Mr. XieZhiping, DLT Regional General Manager also took part in the ceremony.

Mr. Ye Delin, Chairman of NewPearl Group, delivered aspeech with atitle of ‘Dragon Flies with Prosperity, Intelligent ManufactureWins the Future’, explaining the reasons of success for NewPearl’s 28-yearsdevelopment with hard working and exploration spirits. He expressed greatexpectations on the future development of NewPearl Group and also conveyedsincere thanks to DLT team for their efforts in building the world longest energy-saving,intelligent and digitized Carboneutral double deck kiln.

Chairman of Keda Industrial Group, Mr. Bian Cheng,also gave address at the event with warm greetings to NewPearl Group for thesuccessful ignition of the new eco-friendly and intelligent double deck kiln.

In order to promote the progress inCarbon Peak & Carbon Neutral, based on the new stage of development and theimplementation of new development concept, DLT and New Pearl make full use oftheir own advantages in their respective fields so as to apply green functionsto the manufacture and to set up new benchmarks for the green and energy-savingdevelopment of the industry.

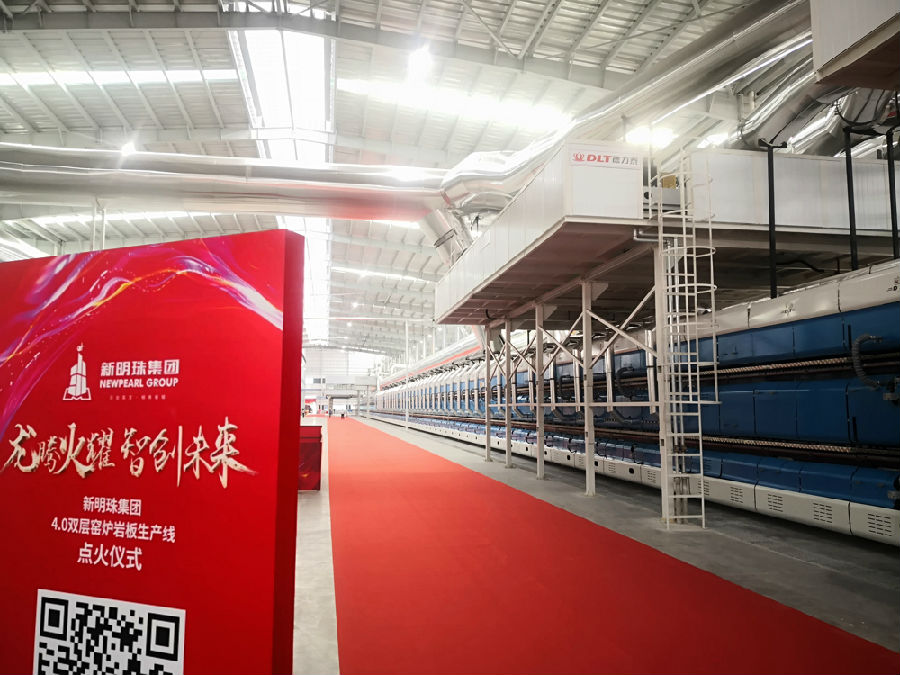

The upgrading project ofNewPearl includes two packages of DLT sintered slab production lines, eachconsisting of a DLT Industrial 4.0 Energy Efficiency BenchmarkDigitized&Intelligent Carboneutral Series double-deck kiln for sinteredslabs (W2350/415.8M), two DHD-EM5 high efficiency 5-layer dryers, double layerpre-kiln dryers and glaze dryers in addition to a HLT latest high efficiencyand intelligent ST400 spray dryer.

The Carboneutral Series double-deck kiln can producedifferent thickness and sizes of high quality sintered slabs in each deck, witha daily output of 20,000m2 of 12mm thickness sintered slabs by bothdecks in total, able to save energy more 10% as a whole. The kiln will be yetanother new flag, leading the building ceramic industry’s upgrading for greenand intelligent plant.

Most important of all, as calculated on the basis of 12mmthickness sintered slabs with the above mentioned output, the kiln can reduceCarbon Emission by 3,000 tons a year at least, answering to the state’s CarbonPeak & Carbon Neutral strategy and fulfilling the enterprise social responsibility.

The double deck kiln is up to now the world longest inlength and largest in output green manufacture double deck kiln. At present,another DLT Carboneutral Series double deck sintered slab kiln for NewPearl’sis also under construction, being the 4th project contract between DLT andNewPearl Since 2020.

The kiln is decorated with DLT Galaxy 5 industrial designfor the kiln outlook. According to the customer’s requirement that theconfiguration should not beout-of-date in 10years, the kiln is equipped withthe advanced digitized& intelligent management system DDI4.0-A, togetherwith innovated technologies for recycled hot air, combustion, insulation,firing control and intelligent integration. For the first time in the industry,the double deck kiln has adopted EHI, OCE, PPC and other single deck kiln’spatented technologies. As a significant breakthrough in double deck firingtechnology, it will be a leading example for the double deck kiln developmentin the future.

With more and more new techniques and experiences insintered slab firing process, while keeping improving product quality by usingnew advanced technologies, DLT has put great efforts in maintaining a stableand consistent green manufacture level, in addition to adding low carbon,energy-saving, eco-friendly concepts to the kiln design, so as to develop thebest sintered slab production line with leading advantages to help customersacquire top markets in the industry.

The successful start-up ofthe project shows the undertaking and wisdom of NewPearl Group and DLT in theachievements of high quality development. It marks the leading position ofNewPearl in smart manufacture as China’s largest ceramics productionenterprise, brightening the group’s goal as to be a 10-billion RMB CeramicEnterprise. “Where you see a construction, where you see New Pearl”. DLT,together with the entire industry, looks forward to a glorious future withNewPearl Group!

簡(jiǎn)體中文

簡(jiǎn)體中文 English

English

News Center

News Center