Since its ignition after the Chinese lunar new year holiday, the GVT production line supplied by Foshan DLT Technology Co., Ltd. to Guangdong Qingyuan Monalisa Building Ceramic Co., Ltd. has been running continuously and successfully, winning full acceptance of the customer.

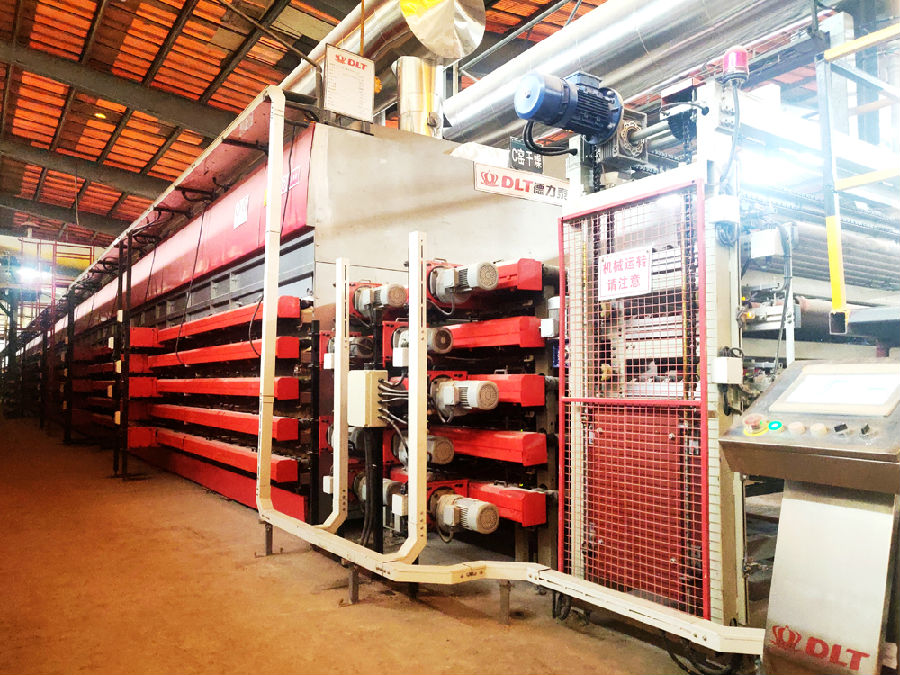

The production line consists of a DLT classic EM-series of five layer dryer, a high efficient and energy-saving firing kiln and other high-performance auxiliary equipment as well as a complete glazing line, mainly producing 800*800mm glazed vitrified tiles with 0.0% water absorption rate. With a daily output of 10,500m2/day, the production line has maintained the first-grade quality rate at above 95% since its being put in use. The total gas consumption of the kiln, five layer dryer, prekiln dryer and glaze line dryer all together is about 1.55-1.6 Nm3 of natural gas / m2 of tile, which marks a new milestone in the innovation of energy-saving kilns in the ceramic industry of China. The line is currently running smoothly, providing high quality glazed vitrified tiles to the markets both in China and overseas.

The exterior decoration of kiln belongs to DLT’s Galaxy series which is targeted at high-end applications. With the cladding of stainless steel sheet panels, the appearance of the whole kiln demonstrates a thorough understanding of the principle of industrial aesthetic designing, while emphasizes the ideas of dynamic, colorfulness, strength and elegancy.

Thanks to the structure with air-tight box-type modules, high efficiency in drying, less occupancy of land and reduced demand in man power, the EM-series of five layer dryer, which is widely being used for drying process, proves its high reliability and good performance. Several patents are utilized in the production line, such as the DHR Heat Recovery System, which realizes a zero discharge of final cooling air for the kiln and a zero consumption of gas for the five layer dryer, the self-suction IFGR burners, the KPR-S and PPC super energy-saving system and the comprehensive optimal energy-saving design, etc. The use of new technology renewed the gas consumption record in the ceramic industry. The high level of intelligentization, automation and informatization of the production line in Monalisa (Qingyuan) Production Base has once again upgraded the definition of ceramic manufacture in the industry.

Along with the development of China’s ceramic industry, Monalisa Group has always been keeping pace with the times. Following the global trend in persuing sustainable development, Monalisa Group adheres to the ideas of green production and environment protection. In answering to the requirement of the times, DLT will join hands with Monalisa Group in the exploring and development of new technologies which will be more energy-saving, more eco-friendly and more sustainable.

簡體中文

簡體中文 English

English

News Center

News Center