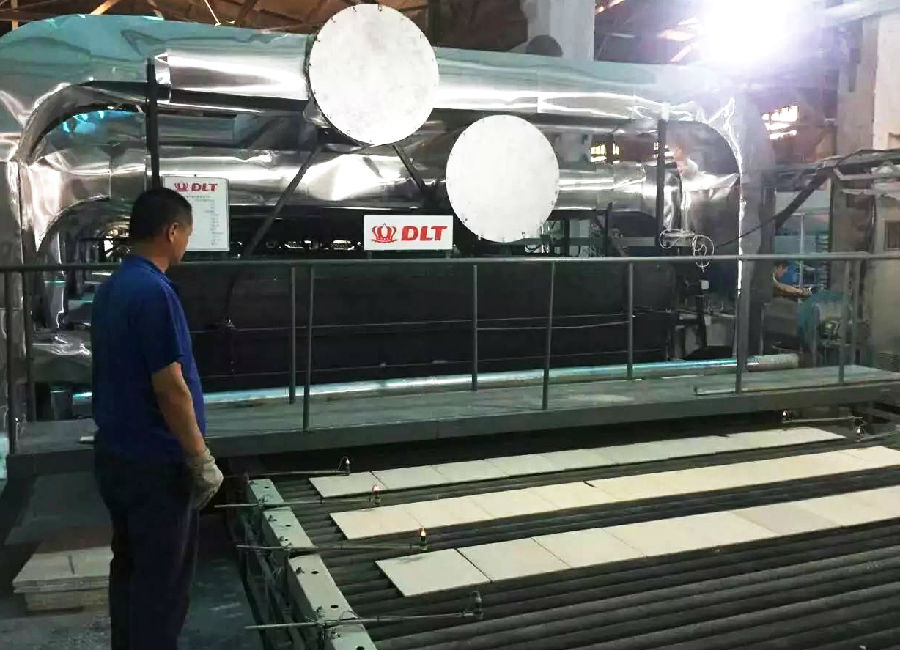

OnMay 31, 2017,supplied and built by FoshanDLT Technology Co. Ltd., two D2D double-layer wide-body firing kiln weresuccessfullyput into production in Shandong Zibo FuLai Te Building Ceramics Co., Ltd. With an inner width of 3500mm,the kilnis now the widest two-layers roller kiln in the world,mainly for production of300 * 300,300 * 450,300 * 600,400 * 800mm tiles, and each of which can reachproductioncapacity of 16,000 square meters per day.

Inresponse to the stricter environmental policy and thanks to technologyprogress, DLT roots its business philosophy with concepts of emission-reduction,energy-saving, environmental conservation in the production line design, withongoing innovation and integration of the latest technology. The reconstructionproject for Fu Lai Te companyrequiresto dismantle theequipments of old and replace with new in the original site, yetwith objectives of fuel replacing, production expanding and fuel saving, whichbringshuge challenge for the entire project.

Consideredthe limited space of shed for two sets of double-layer kiln, meanwhile withconstraints of production capacity no less than 30,000 square meters per day,and30% gas consumption lower than that of the old production line, the professionalteam of DLT brilliantly constituted a vertical-interactive transport system,which ensures smooth transmission for both man and material channels, enablesflexible production switching and convenience for maintenance, making it anmuch more efficient production line.

Withhelpfulsupports from the technical department during the project implementation, DLTerection team overcame lotsof difficulties such as limited space, tightschedule, without any existing experience for reference, etc... And throughharshinsistence in material quality control and strictly detail focused, DLTproved itself with successful project runningand won its reputation with highlyrecognition and praise from its business partner, and set up a benchmark forthe local market.

Thesuccess of the project fully demonstrates that under restrictions such ofstringentenvironmental requirementsand space limitation in the case, only being creativein the mindset and technologycan lead to product innovation, turn impossibleinto possible, andcreate a greater value for clients!

簡體中文

簡體中文 English

English

News Center

News Center